ENERGY STORAGE SYSTEMS - MAXIMUM POWER FOR MAXIMUM RANGE

The range of electric vehicles is determined to a great extent by the performance of the energy storage systems used. Our assembly and testing systems broaden the horizon.

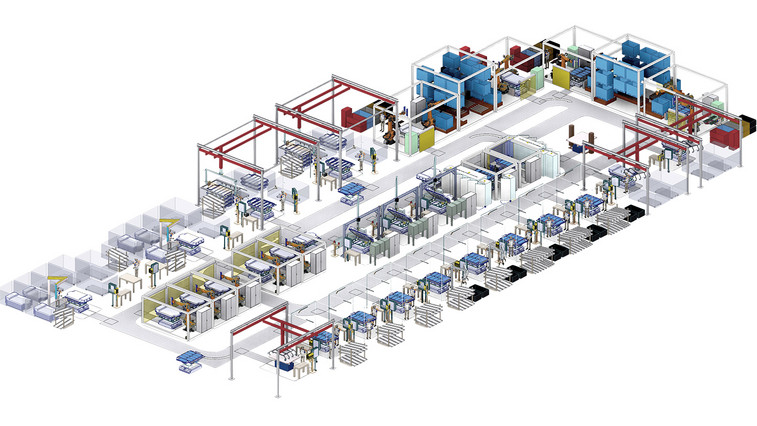

Strama-MPS supplies turnkey assembly lines for pre-assembly of battery modules and final assembly of battery systems for electric and hybrid vehicles. High throughput rates, flexible assembly strategies, sophisticated testing processes and monitored assembly steps characterize our solutions. We combine years of experience in the fields of automation, logistical linking, measurement and testing technology and high-voltage technology.

BATTERY MODULE ASSEMBLY LINES

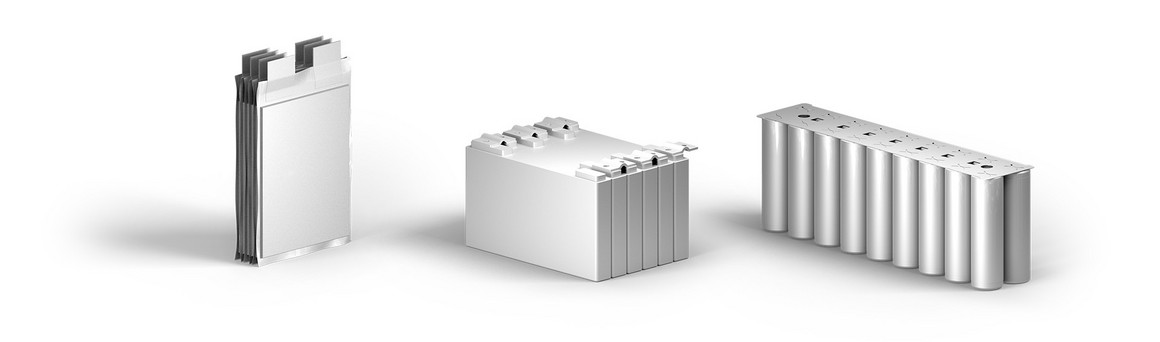

In our assembly lines for battery modules, high-quality prismatic, cylindrical and pouch cells are processed using state-of-the-art equipment. The modules are stacked at high speed and connected electrically. The product portfolio includes: Wire bonding, laser bonding, resistance welding and laser welding. Length and width of the stacks can be freely configured. All modules undergo a 100% function test before being passed on to subsequent processes. Industry 4.0 and consistent traceability are standard in all our systems.

The processing of battery cells requires specific process knowhow and a lot of experience. That is exactly what makes us a leader in engineering. We are thus achieving that finally the full power can be utilized in electric vehicles – at any time and permanently. Even critical issues, such as swelling, overheating, short circuits and salification can be consistently solved with our assembly systems.

Highlights

- Manufacturing of battery modules from prismatic, cylindrical and pouch cells

- Cell stacking by use of state-of-the-art equipment

- High-speed stacking of cells

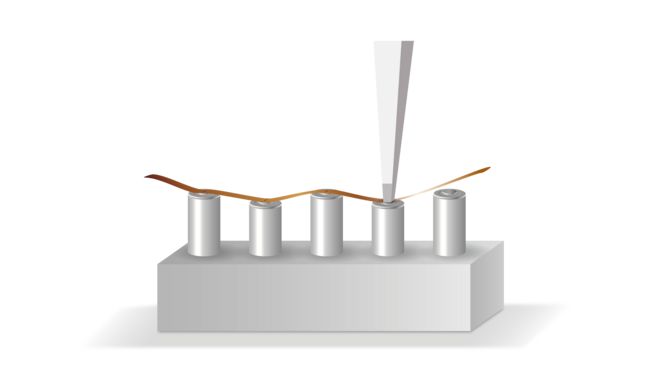

- Establishing electrical connections by means of laser welding

- Future-proof production strategy by variable length and width

- 100 % testing of the modules prior to delivery

- Trackability and traceability

- Full integration of manual workstations, screen-based worker guidance

- Individually adaptable logistics concept: robot, belt system, trolley, etc.

Integrable processes

- Logistics systems / stacking / High-speed handling / pressing

- Faming / solvent cleaning / laser cleaning / plasma activation

- Gluing / applying thermally conductive compound

- Wire bonding / laser bonding / laser welding / resistance welding

- Fixing spacers / foiling

- Labeling / laser marking

- Voltage measurement / impedance measurement / leak test / resistance measurement / image processing / high voltage tests

Innovative connection technology for e-mobility

The quality of electrical connections plays a decisive role for the performance and range of electric vehicles. That is why we use state-of-the-art joining methods for the assembly and wiring of battery modules and battery packs, such as ultrasonic wire bonding, laser bonding and laser tab welding.

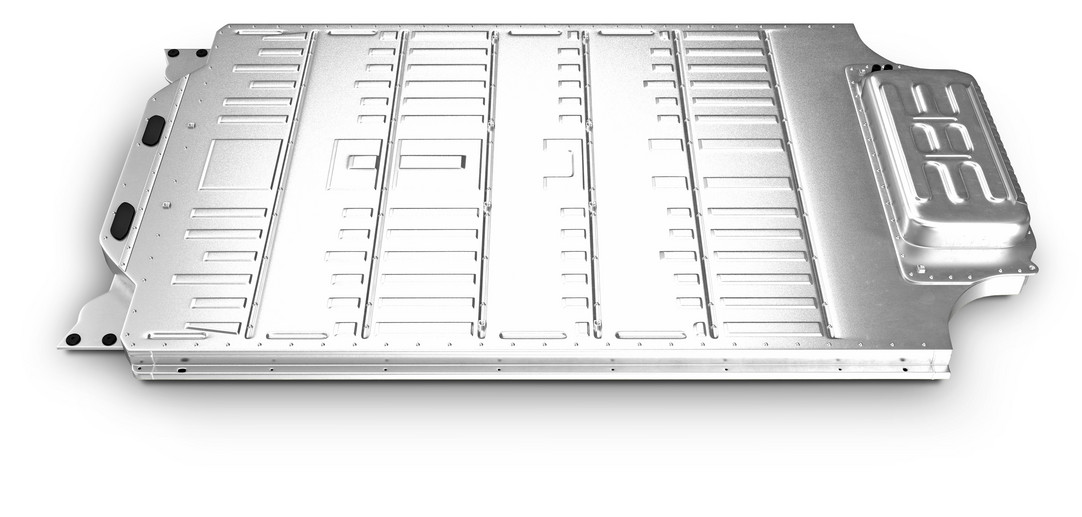

BATTERY PACK ASSEMBLY LINES

In our assembly lines for battery packs the modules are fed into the stations either manually or via specifically developed supply systems. Identification, sorting, positioning, fixing and connecting of the modules carried out fully automatically. Other components, such as cooling systems, ventilation bodies, connectors, wiring harnesses, etc. can be mounted manually or automatically. This involves an inspection step after each assembly station to ensure a zero defect production.

Today’s battery systems are essential, complex and multi-functional modules in electric vehicles. With our assembly lines, the vehicle manufacturers and component suppliers may quickly and easily implement their development ideas. Also for the production of battery trays, we deliver efficient solutions that combine precision with effectiveness and fulfill the highest standards in terms of cleanliness, leak tightness and safety.

Highlights

- Processing of battery modules to battery packs

- 100 % testing of the packs prior to delivery

- Full integration of manual workstations, screen-based worker guidance

- Trackability and traceability

- Individually adaptable logistics concept: AGV, robot, belt system, trolley, etc.

Integrable processes

- Wire bonding / laser bonding / laser welding / ultrasonic welding

- Leak test / high-voltage tests / resistance measurement / flashing / image processing / communication test

- Bolting / gluing / ionizing / thermally conductive paste application / sealant application

- Labeling / laser marking

- Vacuum cleaning / laser cleaning / plasma activation

- Installing wiring harnesses / logistics systems / positioning modules / handling of large components

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/5/a/csm_Fischer__2___8MB___klein__zugeschnitten_9ee777fbe8.png)