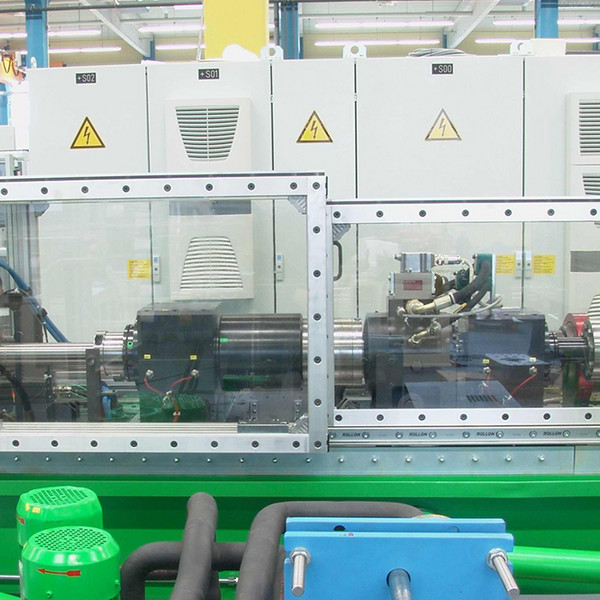

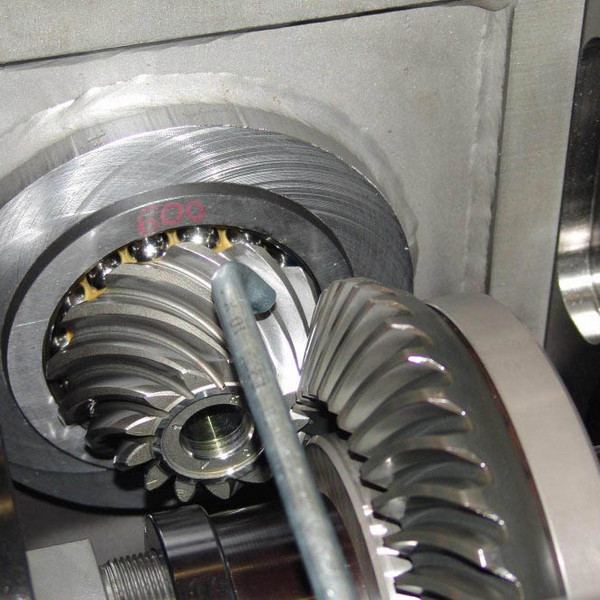

Hypoid gear test rig

The hypoid gear test rig is a test rig with mechanical torque circuit. Two hypoid gears (test and drive gearbox) are paired with a spur gear via a torsion shaft. The complete unit of hypoid and drive gear is designed as change speed gearbox. The load torque is applied via a hydraulic load torque clutch. The test rig is driven by a variable-speed asynchronous main spindle motor. The test rig is designed

as a programmable load cycle test rig for long-time tests. The hypoid test gear can be operated with splash and injection lubrication. The oil conditioning used in injection mode for the test and drive gearbox consists of controlled heating and cooling in a range from -20 °C to 140 °C and oil filtration. The quantity of oil injected can be set in a range from 0 to 10 liter/min.

Highlights and tests

- Programmable load cycle test rig

- Variable speed

- Variable load torque

- Vibration monitoring (e.g. scuffing detection)

- Evaluation by means of LabVIEW

Optional:

- Cooling/heating

- Network connection

- Long-time tests rear-axle drive

- Especially designed for high speeds

- Characteristic values obtained: Speed, torque, temperature, vibrations

- Targeted industries: Automotive- and petroleum industry

Technical data and equipment

- Speed: 0 – 6,000 rpm

- Variable speed: 0 – 100,000 rpm

- Torque: 0 – 3,000 rpm

- Temperature: -20 °C – 140 °C

- Vibration monitoring