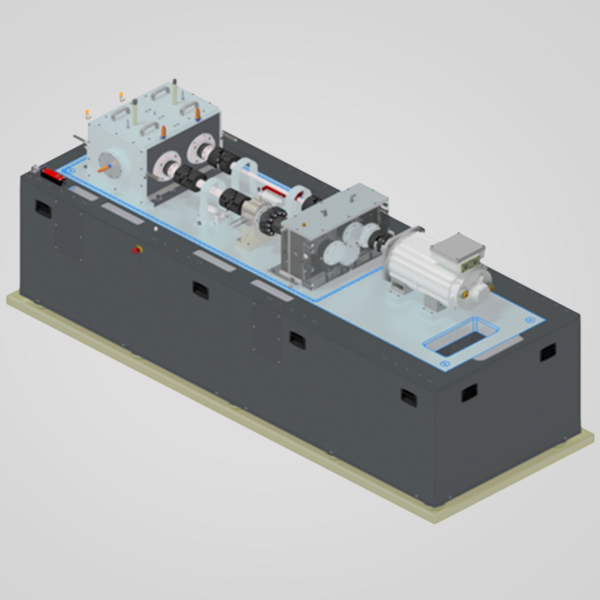

Bevel gear test rig

The bevel gear positioned in the test gear box is the special feature of this test rig. The test gear can be run with splash lubrication or with injection lubrication. An individual oil supply unit is assigned to each of the gear boxes. The temperature of the gear oil is controlled via a combined cooling and heating system.

The entire test rig can be controlled via a touch screen panel. Programmable set-point values are used to allow dynamic adjustments of rotational speeds and gear oil temperature values during the test run. Variable parameters can be preset in the programs for both the motor speed and the gear oil temperature.

Highlights and tests

- High rotational speed at the pinion (10,000 rpm)

- Torque is generated manually

- Sump-type and injection lubrication

- Programmable test runs allowing dynamic presetting of rotational speed and temperature

- Structure-born sound vibration monitoring

- Measuring data (up to 50 kHz) available as .tdms and .csv files

- Adjustable limit value monitoring

- Graphic display of measuring values

- Individual oil supply unit circuits for drive and test gear boxes

- Gear wheel fatigue tests, oil tests, wear tests

Technical data and equipment

- Rotational speed range: ±4500 rpm at motor

- Gear ratio: 2…5

- Max. torque: 600 Nm

- Max. power in the torque circuit: 285 kW

- Center distance: 260 mm

- Soaking temperature for injection lubrication: 70°… 100 °C

- Oil flow: 0.5 – 10 l/min

- Weight: approx. 5 t

- Footprint (L x W x H): 5.4 m x 3.6 m x 2.2 m