POWERTRAIN - COMPETENCE IN E-DRIVE PRODUCTION

Innovative electric drive concepts improve driving dynamics. They will revolutionize driving experience as well as automotive engineering. We provide the necessary assembly technology.

Compared to combustion engines, electric drives are simple and cost-effective components. This will lead to increased competition in this segment, decentralization of production and further modularization in the automotive industry. This calls for innovative concepts that combine profitability, flexibility, quality and precision.

Our turnkey assembly lines for e-axles, e-motors, stators and rotors offer our customers this combination. Due to relatively high standardization in this segment, we are able to guarantee the shortest project and delivery times. We offer design, construction, production and commissioning of all production processes for e-motor and e-axle assembly with our well-known Strama-MPS quality.

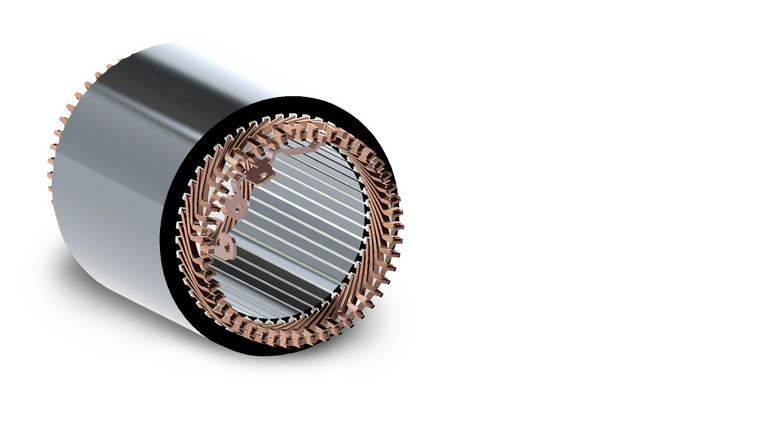

ASSEMBLY LINES FOR STATORS

Demands to power density and system weight are becoming increasingly higher. Therefore, an agile and innovative engineering in motor development is also required. The power potential of stators can be significantly increased using new winding methods and the pin technology with rectangular wires. We can provide you with the assembly and connection technology.

Processes, such as the stripping of copper wires, the twisting of pins or the contacting by means of ultrasonic laser bonder or wire bonder, have been completely automated. We also specifically design impregnation machines for your products and integrate them seamlessly into the production line.

Assembly scheme of a high-performance stator

Highlights

- Integration of all process and test steps of stator production

- Production of different pin shapes (U / I / Hair)

- Inline pin – variant production from the coil

- Electrical connections using state-of-the-art bonding processes

- Modular design for individual ramp–up-scenarios

- High-speed processes “on the fly”

- Trackability and traceability

- Inline quality inspection

Integrable processes

- Laser welding / gluing / bolting / bearing assembly

- Pin preparation / twisting / pressing / hardening

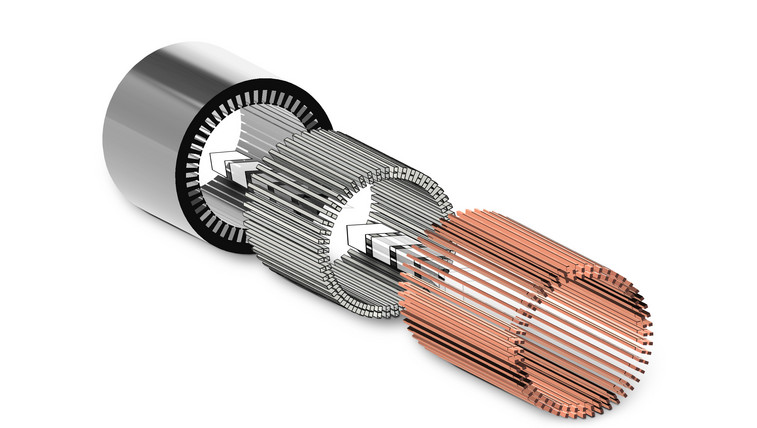

ASSEMBLY LINES FOR ROTORS

Basic requirement for a high-quality rotor produc-tion is the reliable supply and fitting of the stacks with magnets. Shafts and rotors are assembled in our production lines under strict quality control. The components are fixed by means of specifically designed joining technol ogies, such as bolting, gluing and pressing.

Assembled and balanced rotor – ready for installation

Balancing is carried out fully automatically – as option, an additive or subtractive process. Magnetizing is individually adaptable.

Even functional tests, e.g. of the press-out forces, the balance quality or the magnetization, are integrated by us into the process according to your needs.

Example of a rotor assembly line

Highlights

- High-speed handling for inserting magnets

- Highly automated stacking

- Diverse fixing technologies

- 100 % test of balance quality and field strength

- Trackability and traceability

- Individually adaptable logistics concept: Robot, belt system, etc.

Integrable processes

- Mould injection / gluing / hardening

- Inserting magnets / high-speed handling

- Magnetizing / balancing / testing

- Bearing assembly / installing retaining rings

- Laser marking / laser welding

- Pressing / force-fitting / bolting

- Inductive heating / active cooling

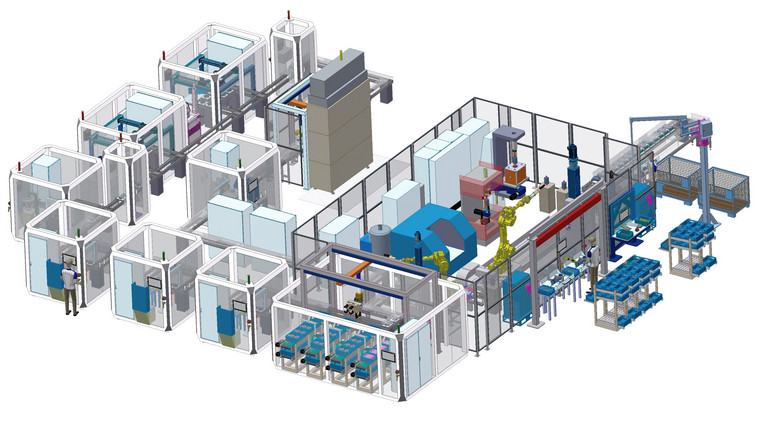

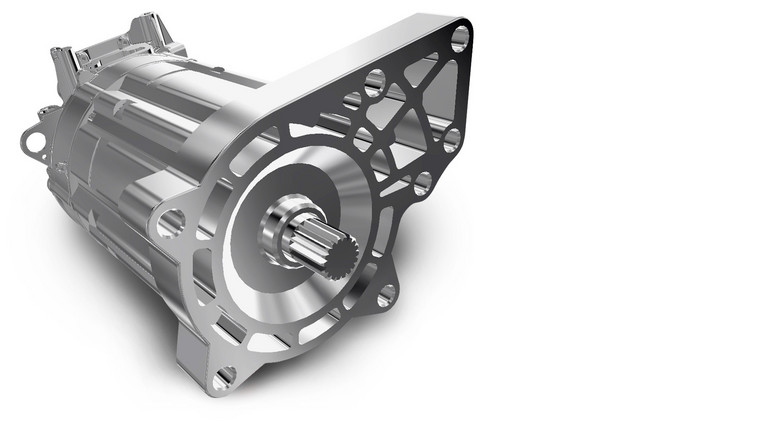

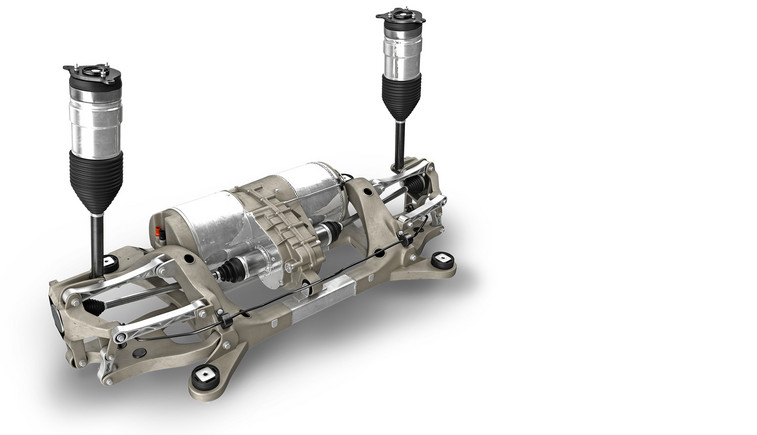

ASSEMBLY LINES FOR E-MOTORS INCLUDING TRANSMISSIONS AND E-AXLES

As a leading system supplier in e-mobility we de-velop and realize highly modern assembly lines for you, which are flexible enough for a production of varying types of powertrains. Centerpieces are the stations for the assembly of electric motors.

Assembly lines for e-motors

Transmission assembly, inverter manufacturing and End-of-Line testing of the powertrain are also perfectly covered by our modular technology platform.

Assembly lines for e-axles

Highlights

- Turnkey assembly lines entirely from a single source

- Integrated inline- and EoL tests to ensure the functionality and product quality

- Flashing of software version

- Optimum handling of large components Human-robot collaboration

- Individual automation level

Integrable processes

- Installing cable harnesses / logistics systems / handling of large components / component handling

- Leak test / HV & ISO tests / flashing / seal mounting

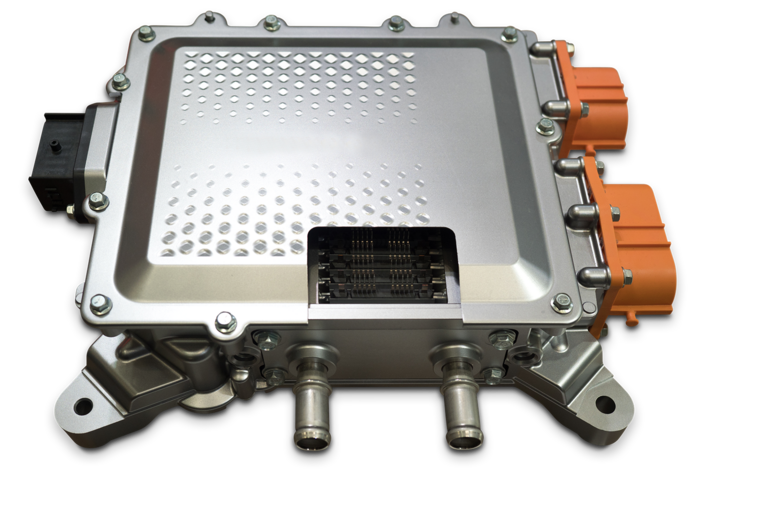

ASSEMBLY LINES FOR POWER ELECTRONICS

New and sustainable drive technology products in various mobility sectors result in new as well as challenging tasks for their automation, assembly and testing. To be able to react to the volatility of the market, intelligent, scalable and flexible concept solutions are required which meet the highest automation / assembly and test standards.

Based on a broad process and automation knowledge of electronic, electrical and mechatronic products we offer reliable and highly efficient solutions in the sector of power electronic assembly. The standardized Strama-MPS technology platform ProMoCell is the basis for scalability and flexibility. Our Strama LineDataServer is recording all machine and operating data and is the interface to your Manufacturing Execution System (MES).

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/5/a/csm_Fischer__2___8MB___klein__zugeschnitten_9ee777fbe8.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/0/2/csm_Pasker_Roland_bd9eb2ea59.png)