ENERGY RECOVERY IN THE POWER CIRCUIT

A test rig operating on the principle of a closed power circuit can save up to 95% of energy as compared to a brake test rig. The energy fed into the system is contained between test and drive gearbox is by applying the torque to the clamping fixtures via one of the two connecting shafts. After start-up the test energy completely remains in the test circuit - except for gearing and bearing losses – so that the drive itself only needs to supply the 5% of lost energy.

Our test rigs at a glance

In addition to the standardized FZG gear test rig we also develop special test rigs such as test rigs for hypoid gears, spur gears and drive shafts. Our test rigs meet customer requirements for dynamic load cycles, efficiency evaluation, oil conditioning, vibration analysis and telemetric signal exchange. In addition, the loads and stresses the test specimens are subjected to can be displayed by means of the energy-efficient motor/generator principle.

Profit from the knowledge and expertise we were able to gain from more than 200 test rigs for the aviation, automotive and petroleum industry which we have so far installed at our customers’ sites!

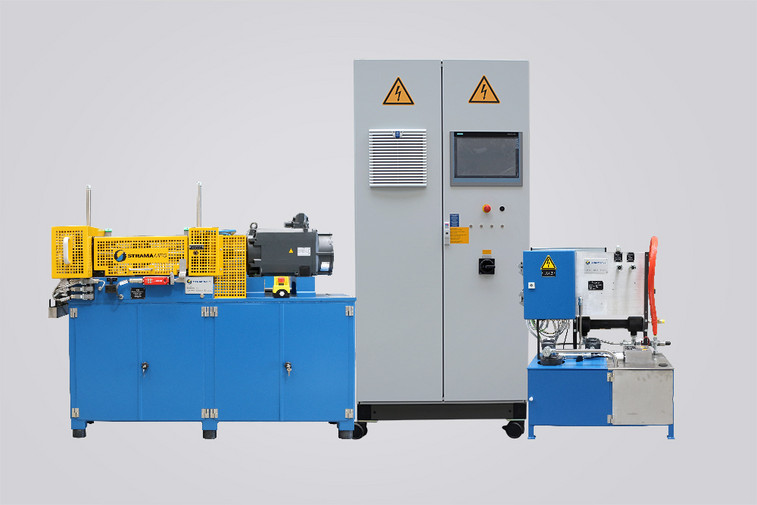

FZG gear test rig

The FZG gear test rig used to test the service life of lubricants and gear wheel materials is exclusively built by Strama-MPS under license of the TU Munich. The standardized testing procedure allows for comparisons with other products and materials, guarantees repeatability of the tests and thus significantly contributes to assure optimum quality for the lubricant industry.

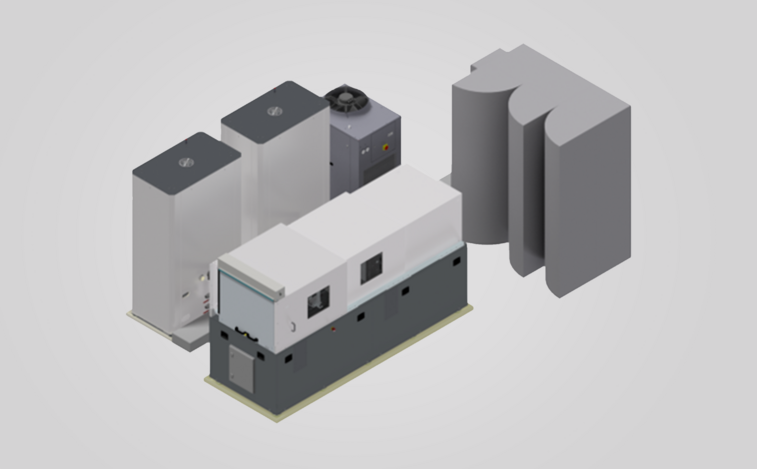

Gear test rig highspeed

The high-speed test rig has been developed on the basis of the FZG torque-bias gear test rig. The power circuit principle was maintained. The drive gearbox and the test gearbox are frictionally engaged by two torque shafts. The circuit load is applied by a load clutch via a tension ratchet.

System Flender oil foaming test ISO 12152

As a rule, oil manufacturers test the foaming characteristics of their oils in accordance with the ANSI / ASTM D 892 method and/or a similar method pursuant to DIN 51566, i.e. by injecting air into the oil sample over a preset time. As the results from this test frequently do not match the foaming characteristics detected in gearboxes, it was necessary to develop a test setup focusing on actual operating conditions. In the Flender foaming test, a gear pair rotates in the oil to be tested and thus mixes an air-in-oil dispersion. The surface foam, the volume change of the air-in-oil dispersion as well as its reduction are tested under actual marginal conditions which occur in gearboxes.

Bevel gear test rig

The bevel gear test rig has been developed on the basis of the FZG torque-bias gear test rig. The power circuit principle was maintained. The drive gearbox and the test gearbox are frictionally engaged by two shaft trains. The circuit load is applied by a load clutch via a tension ratchet.

Bevel gear test rig TS-30

The bevel gear test rig allows testing of bevel gear sets of different sizes for wear and fatigue strength. Electric drives initiate the rotary motion (motor) at the drive side and the braking torque at the output side (generator). This concept permits running the test rig in a very energy-efficient way.

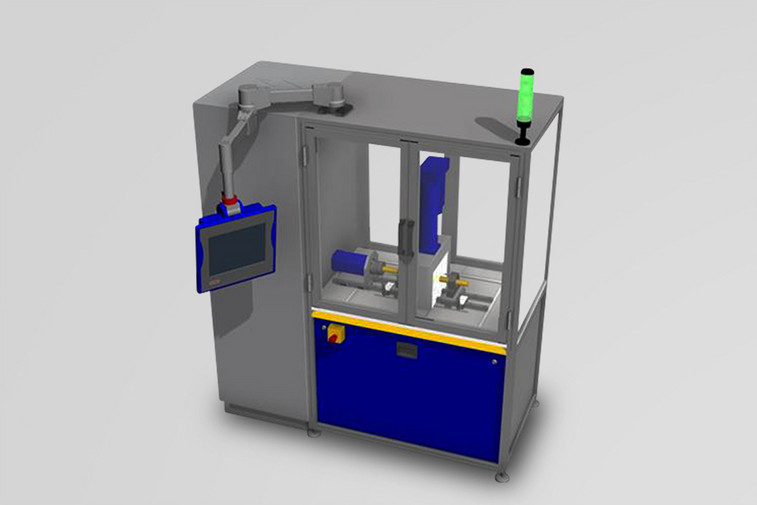

Antifriction bearing test rig / slide bearing test rig

This bearing test rig is used to test different types of antifriction and slide bearings and/or bearing/shaft combinations for wear and/or fatigue strength. A mechatronic actor allows the dynamic simulation of the radial forces and/or deflection of the shaft during the test run; testing temperatures can range between -40 and +150 °C. During the test run the speed, the torque, the vibrations, the force, the travel, the oil pressure, the oil flow rate and the temperature are continuously recorded and evaluated by the system control. At the HMI the test runs can be individually programmed and the test results can be graphically displayed.

Gear test rig with variable center distance

This special test rig in space-saving design allows for the testing of various gear wheel designs at center distances from 89 to 140 mm. Thanks to the high applicable torque of up to 1650 Nm and maximum speeds of up to 6000 rpm it is especially suited to determine the maximum duty values of lubricants for high performance motors.

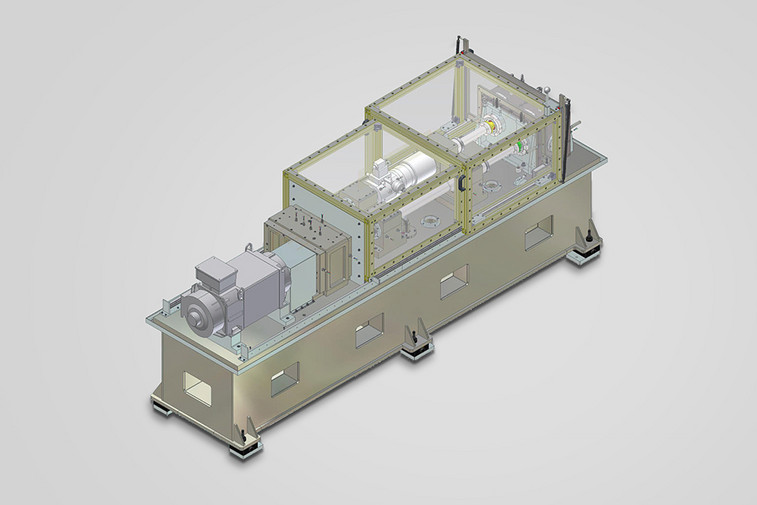

Hypoid gear test rig

The programmable load cycle test rig for rear-axle drives is designed for long-term tests at high torques. Two hypoid gears (test and drive gearboxes) are paired with a spur gear via a torsion shaft; for dynamic tests the load torque is automatically applied by means of a hydraulic load clutch.