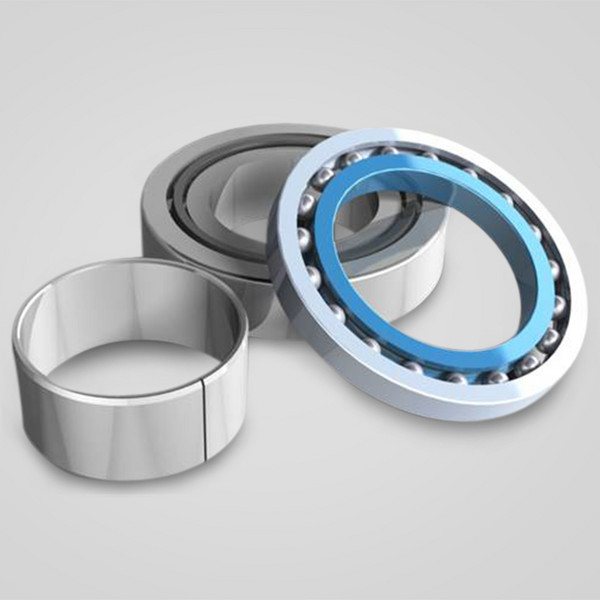

Antifriction bearing test rig / slide bearing test rig

Highlights and tests

- Programmable antifriction bearing test rig

- Variable speed

- Variable force application

- Variable tilting and skewing of the test bearing

- Slip measuring

- Oil lubrication with adjustable injection angles

- Evaluation by means of LabVIEW

Optional:

- Cooling / heating

- Ventilation

- Network connection

- Testing of antifriction and slide bearings and/or bearing/shaft combinations for wear and/or fatigue strength

- Simulation of high force frequencies

- Especially designed for high speeds

- Characteristic values obtained: Speed, torque, temperature, vibrations, efficiency level

- Targeted industries: Automotive- and petroleum industry, antifriction and slide bearing manufacturers

Technical data and equipment

- Variable speed: 0 – 100,000 rpm

- Variable radial force: 0 – 200 kN

- Variable axial force: 0 – 200 kN

- Tilting/offsetting of bearing

- Temperature (cooling and heating): - 40 °C to + 150 °C

- Vibration monitoring

- Dimensions: 4000 x 2200 x 2000 mm