TEST SYSTEMS FOR BATTERY ASSEMBLY

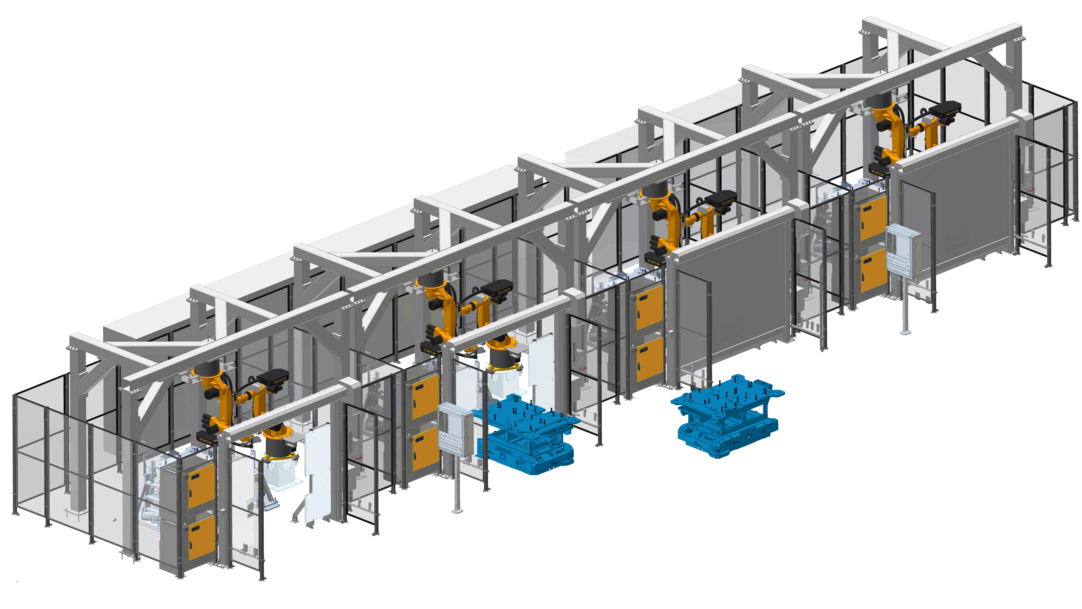

As a system supplier we also offer modern test systems for module and pack assembly lines. This allows a perfect carrying-out of all target-oriented Begin-of-Line-Tests (BoL), inline function tests and the final End-of-Line-Tests (EoL).

Quality gates can be defined during the inline function tests and, for example, resistance meas-urements and leak tests be made. Interim tests secure the value-added chain in every process step. Potential faults can be detected and elimi-nated at an early stage. EoL test rigs ensure the overall functionality of assembly and safety systems.

For contacting special connectors are used. These enable realizing – maintenance-free – several hundred thousand mating cycles.

Test protocols for every task

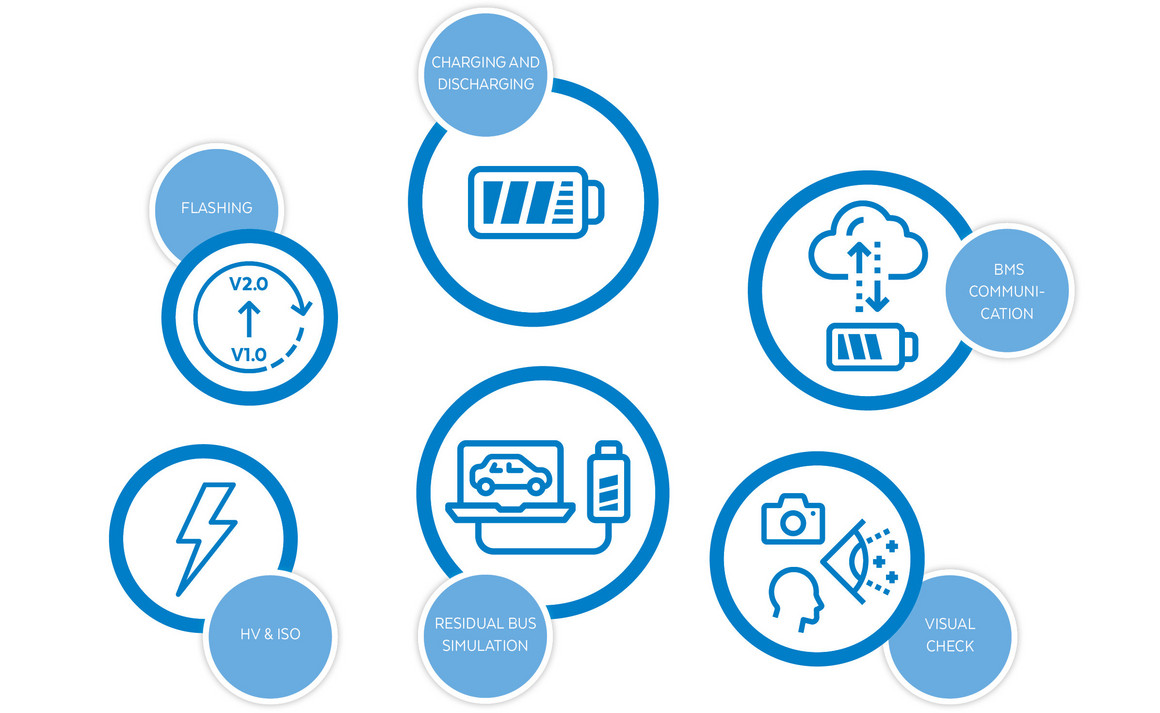

Today, bus systems are used for ex-changing signals in vehicles. Based on the application and requirement (such as safety-critical applications, high data transfer volumes, flash programming capability or cost aspects) different test and communication protocols are used.

We integrate the protocol that optimally suits your individual testing tasks into the EoL tester. The outside world and its influences are simulated via a residual bus simulation.

Communication Protocols

- CAN (CAN – FD, XCP)

- FlexRay

- Automotive Ethernet

- Lin

- MOST

- UDS

Key Figures

- Power: 1200 A

- Voltage: 1200 V DC

Guaranteed Range and Safety

With our test rigs and devices we ensure the performance and capacity of battery systems. By applying HV and ISO tests we provide flashover protection. The function test outside the vehicle is made with Hardware-in-the-Loop-Simulations (HiL).

The proper functioning of the safety shutdowns is also checked in this process – for example the temperature and crash sensors.

From: Begin-of-Line Test (BoL) – to: Inline function tests / quality gates – all the way up to: EoL test

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/5/a/csm_Fischer__2___8MB___klein__zugeschnitten_9ee777fbe8.png)