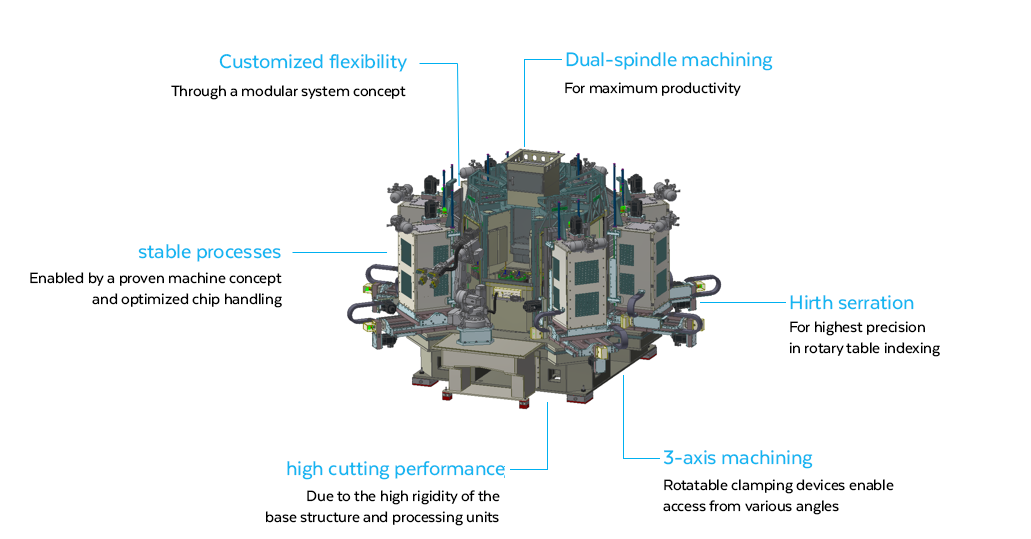

RT MAXX

Flexibility and robustness

The RT Maxx combines a stable and sophisticated design with multi-axis processing units and thus forms the basis of a highly productive and scalable transfer system for series production.

A machine concept that can be specially configured to your product and your requirements in conjunction with the latest CNC technology enables the processing of a wide variety of materials for components with edge lengths of up to 160 mm.

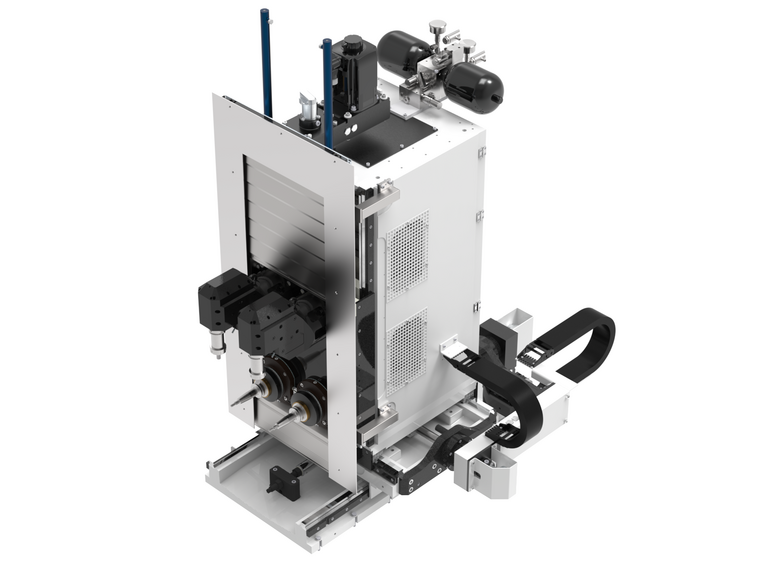

Clamping device concept

In addition to standardized clamping systems, the RT Maxx also offers the option of selecting from a wide range of modular systems to create a clamping concept that is optimally tailored to the product and the machining situation in the usual Strama Engineering quality.

- Minimal set-up times thanks to zero-point clamping system and quick-change concept for planetary superstructures

- 360° machining possible thanks to two rotatable carrier planets

- High repeat accuracy of clamping with up to four separate hydraulic clamping circuits

- Variable clamping force adjustment per clamping circuit for changing requirements

- Active monitoring of component clamping for maximum process reliability

Machining units

The RT Maxx is able to perform a wide range of machining operations thanks to the option of adding specific units specialized for the product and process in addition to the standard three-axis units.

- High dynamics for demanding machining operations in all common materials

- Freely configurable spindle combinations with up to 4 tool spindles per standard unit

- Machining operations can be mapped from different angles

- Special units for special requirements such as broaching or multi-spindle heads in the modular system

- Individual processes can be integrated on customer request

Sinumerik ONE and digital twin

Sinumerik ONE is the future-oriented CNC system for highly productive machine tools and complex machining operations. In combination with the advantages of the digital twin, a new dimension of productivity and flexibility in production is achieved.

- Strama standard software for machine tools enables detailed and fast visualization of the machine

- Up to 10 times faster PLC cycle times and less non-productive time thanks to Siemens S7-1500-PLC

Digital twin as optimization for the entire system life cycle

- More efficient project planning phase thanks to parallelization of processes and shorter commissioning times

- Realistic machining simulation and virtual work preparation

- Integration of new product variants in the ongoing production process

- Optional Sinumerik Edge offers integrated quality management and predictive maintenance

Direct request

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/c/a/csm_Muehlbauer_Thomas_Neu_2024_805a71e4da.png)