Automation solutions for sensors

FOR AUTONOMOUS AND SAFE MOVEMENT IN THE FUTURE

Today’s passenger cars are equipped with approximately 100 sensors whose signals ensure our safety as well as our driving comfort and are responsible for the smooth running of all technical processes. As the technique of autonomous driving will revolutionize our ways of transport and mobility, the need for sensor systems will multiply. No reason to worry! With Strama-MPS flexible solutions you will be optimally equipped for the future.

Assembly and testing systems for sensors

With their customized scalability and the opportunities they provide for diversification, our machines and lines can offer the decisive head start in a competitive market. Strama-MPS is your manufacturer for assembly and testing machines for high-quality sensors and control units such as:

![[Translate to English:]](/fileadmin/_processed_/e/d/csm_strama-sensorik-surroundview-camera-linie_assembly_34530ff020.jpg)

Lidar

Experts agree: Autonomous driving from SAE-Level 3 requires a third “eye” besides camera and radar. The Lidar (light detection and ranging). From the emitted laser pulses and the laser light that is scattered back, the distance of a static or moving object is calculated over time. Very high resolutions with a long range also to unfavorable environmental conditions can be realized.

Strama-MPS can rely on a comprehensive knowhow in the sector automation of electronic, electrical, mechatronic and mechanical products, in particular camera and radar sensors. This knowledge is used to create individual and tailored concept and automation solutions of Lidar products for our customers.

Brake system

Safe braking in a difficult situation and at the same time keeping the vehicle under steering command is one of the most important ADAS-functions of modern auto-mobility. Full-integrated ABS-/ESP-systems are installed in every new vehicle today.

We have an extensive knowhow in automation and assembly of single components of the brake system up to the complete system of the mechanical module and electronic module of the brake system. Consistent traceability in Industry Standard 4.0 ensures a secure process and quality data acquisition and evaluation.

From the semi-automated up to the fully automated assembly and test system, we have realized a wide range of projects according to customer requirements.

Surround view camera

Surround view cameras which are installed in the front and rear of our cars as well as in the exterior mirrors are the first step towards autonomous driving. An increase in the number of automobiles produced as well as upcoming guidelines regarding energy efficiency and safety will result in a multiplied demand of control units and sensors. With our fully automatic assembly and testing machines for surround view cameras we are optimally equipped for the future demands of the market.

Learn more

Pressure sensor

Today all kinds of pressure sensors are used in most of the systems in our cars, e.g. in the intake system or the brake system. Our calibration systems subject these sensors to various quality tests both under room temperature as well as after heating them under high temperature before calibrating them. Calibration is done in several stations where the components are electrically and pneumatically contacted and where the sensors are subjected to a controlled pressure.

This process is monitored by complex measuring systems. Once the calibration has been successfully completed, a marking laser applies a DMC to the component and it will be discharged as good part.

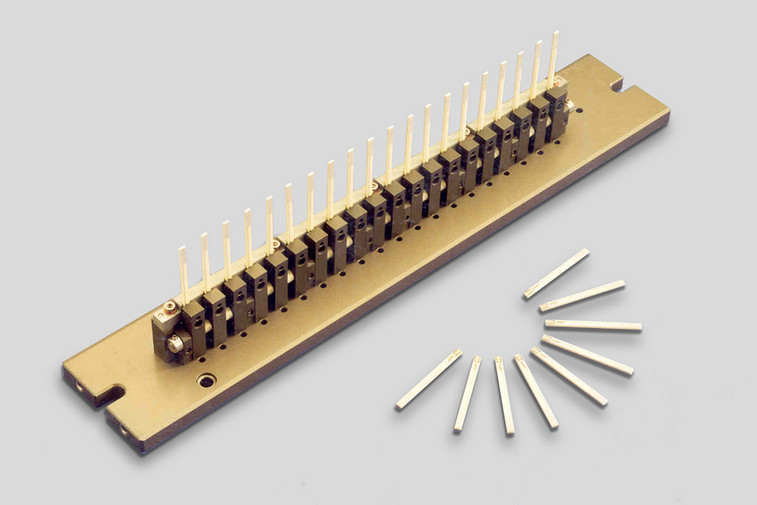

Sensor element

Ceramic sensor elements are integrated in lambda probes used for vehicles. Our conditioning and testing machines can be used to subject the workpieces to various testing processes during which electric function variables are measured at the sensor element. Voltages in a range of mV - µA are measured and evaluated during various multiple tests carried out one after the other. Additional tests are carried out under preset atmospheric conditions at operating temperature. After discharging from the testing stations the sensor elements pass through an electrolyte impregnation unit as well as a conveyor belt furnace. The lines feature a modular design thus allowing a step-by-step capacity extension.

Lambda sensor

For many automobile manufacturers the future lies with electric drive systems. In the years to come the internal combustion engine will nevertheless play an important role, even though it will be combined with an electric motor in form of a hybrid powertrain. This is why automobile manufacturers will continue to invest in production lines for internal combustion engines. The lambda probe is one of the key components of the gas engine. For many years our customers have been relying on our assembly and testing machines with pre- and final assembly for lambda probes. Changeover is carried out automatically thanks to a connection of the machine to the master computer. The individual components are fed to the machine and sorted automatically; they are then assembled in pressing and joining stations with process monitoring. Consumption data measuring and recording, semi-automatic measuring and testing routines as well as a fully automatic final inspection are additional highlights of our machines.

![[Translate to English:]](/fileadmin/_processed_/1/0/csm_IMG_5419-2_Radarsensor_freigestellt_web_Clipping_87a8e915c0.png)

Radar sensor

Radar sensors play an extremely important role in the world of autonomous driving. Radar is one of the key technologies for the development of advanced driver assistance systems (ADAS) that are able to instantly measure distance, angle and speed and generate detailed images of the environment. We offer highly automated assembly and testing systems for the production of various radar sensors. Process, operating and machine data are recorded and evaluated in almost real time via an integrated MES system. Our systems also meet the highest ESD requirements.