Innovative connection technology for e-mobility

The quality of electrical connections plays a decisive role for the performance and range of electric vehicles. That is why we use state-of-the-art joining methods for the assembly and wiring of battery modules and battery packs, such as ultrasonic wire bonding, laser bonding and laser tab welding. Flexible surfaces, slight surface impurities and differences in height are thus managed just as confidently as a precise position detection and control.

F & K DELVOTEC is a subsidiary of the Strama Group and with more than 40 years of experience the recognized international technology leader in ultrasonic wire and laser bonding.

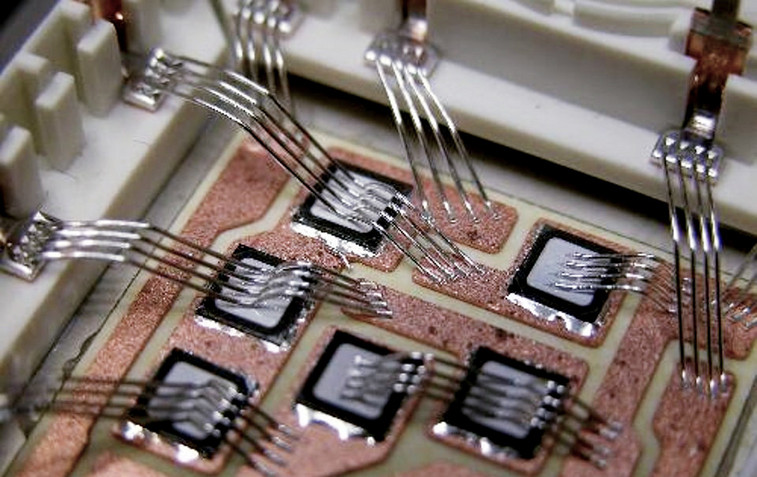

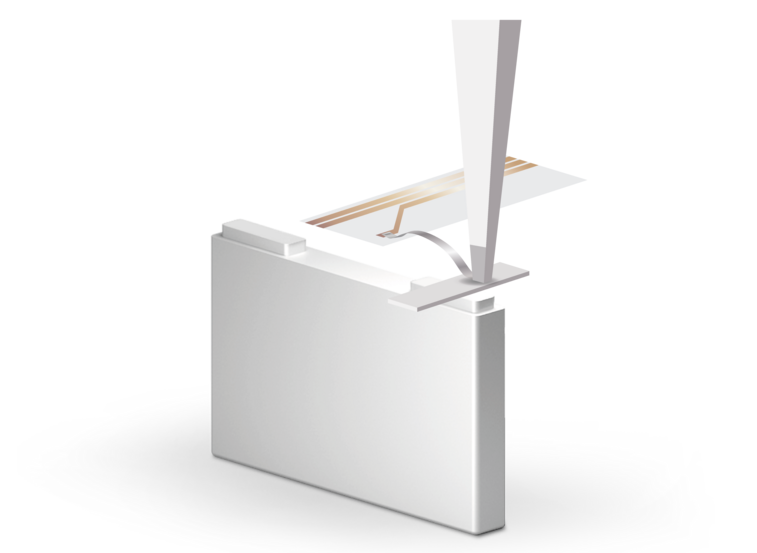

Ultrasonic Wire Bonding

Ultrasonic wire bonding is the preferred method for the wiring of electrical contacts in sensitive sensor systems, semi-conductor and control electronics. Wires up to 20 A or ribbons of aluminium or copper

can thus be processed flexibly. The energy input into the cell is low. The investment pays off quickly thanks to high productivity.

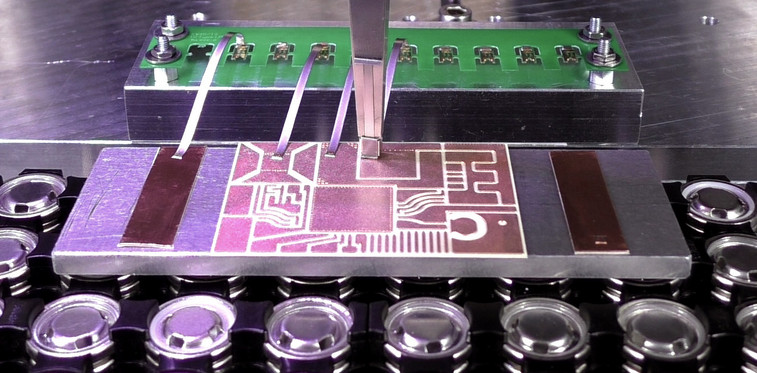

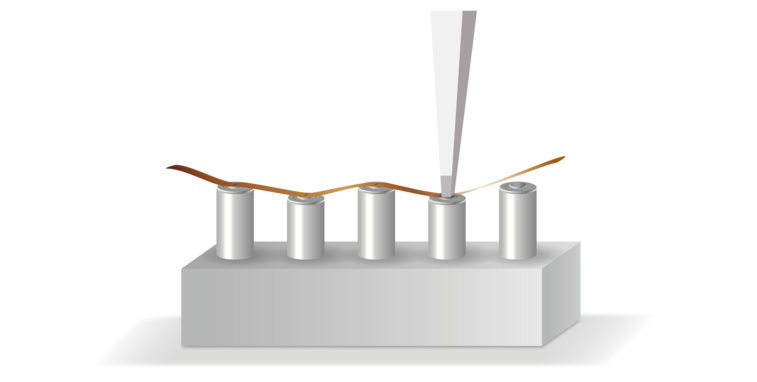

Laser Bonding

Laser bonding is the leading connection technol-ogy, which is used wherever large cable cross sec-tions are required for a high power transmission. Wires up to 60 A and ribbons up to 10 x 0.5 mm of aluminium or copper can be connected without problems according to the current development status. As an alternative – depending on the requirement and product – Laser-TAB bonding is also available for any cross sections.

Market-specific solutions for the industry

Our connection technologies are used for a wide variety of industrial applications – also in the production of powertrains, sensors, control units and other electronic devices. Strama-MPS has many years of experience in integrating all common and innovative processes.

Integrable processes

- Laser bonding of ribbons

- Laser-tab welding

- Ultrasonic bonding of thin wire connections

- Ultrasonic bonding of thick wire connections

- Ultrasonic bonding of heavy ribbons

- Process simplification

- Excellent height tolerance

- No additional components

- No clamping

- Copper connections

- Aluminium connections

- Gold connections

- Hilumin connections

Printed Circuit Board Assemblies

- Simple product optimization

- Bonding of unsupported PCBs

- Avoiding potential pre-cleaning of the printed circuit boards

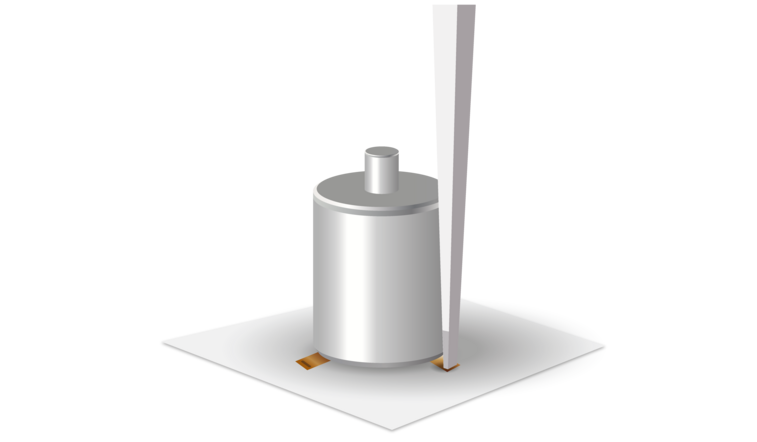

Energy Supply

- Connections with low induction

- Simple high-performance connections

- Simple product optimization

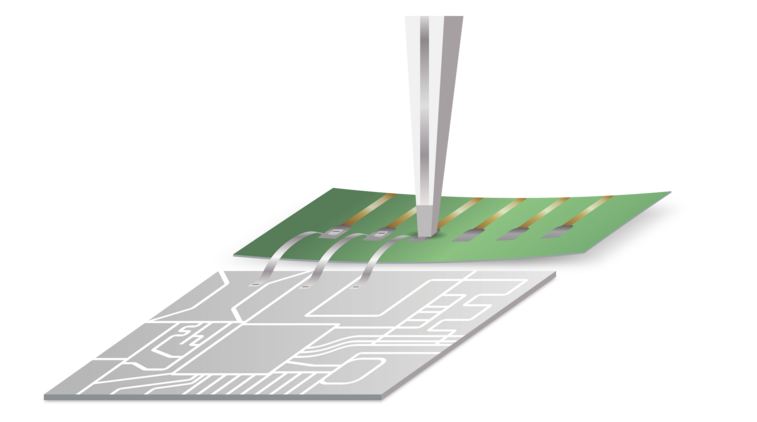

Flexible Printed Boards

- Welding depth precision

- High-quality connections

- Simple product optimization

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/5/a/csm_Fischer__2___8MB___klein__zugeschnitten_9ee777fbe8.png)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/6/3/csm_Pasker_Roland_bearbeitet_4f7ed977f8.png)