PRODUCTION SYSTEMS WITH BASIC MACHINE PLATFORM ProMoCell® TSX & FSX

The ProMoCell® is our machine platform for all your production, assembly and testing processes. Its tasks can be flexibly expanded, it is quickly available, robust and yet mobile, helping you save time and costs. Furthermore, it features an impressive ease of servicing and very effective occupational safety and ESD protection. The ProMoCell® is available as a table version (TSX) and as a floor-level version (FSX).

YOU HAVE THE CHOICE!

Flexibly adapt our machine platform ProMoCell® to your requirements.

Transparency

Real glass or Makrolon? It depends on the application. Glass is easy to clean, scratch-resistant and provides optimal visual contact to all components. Makrolon offers advantages by its impact strength, e.g. when using robots. For ESD applications, antistatic Makrolon is chosen.

Laser protection

For extensive laser applications ProMoCell® also provides the laser protection – according to the currently applicable regulations and standards.

Control

For ProMoCell® TSX the control cabinet can optionally be integrated above or underneath the table top. For the FSX-version the control cabinet can also be placed on top – or over the entire height of ProMoCell®.

Vertical expansion

If the standard heights of ProMoCell® TSX and FSX should not be sufficient, a roof hood of 600mm offers “much scope for more”. The roof hood is additionally expandable in increments of 200mm.

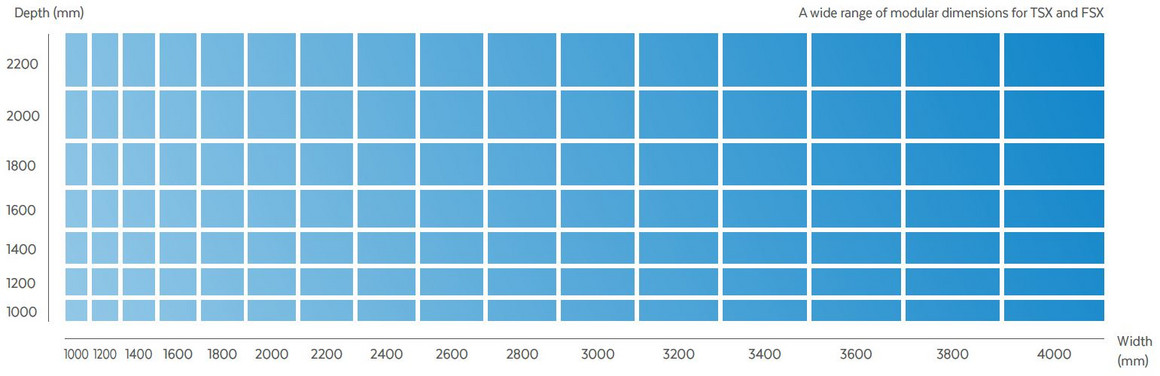

INTELLIGENT GRID AND MODULAR CONCEPT FOR ANY SPACE REQUIREMENT

With their variable grid dimensions, the ProMoCell® TSX and FSX offer space for any process structure. The overall height without support arm and signal lamp is 2265 mm or 2715 mm in the high variant (with 100 mm ground clearance). Between 1000 – 2200 mm in depth and 1000 – 4000 mm in width all dimensions can be freely selected and combined in increments of 200 mm.

EASE OF USE TIMES THREE

Three different operating concepts and a special feature sensure optimum handling and comfort – according to your needs and process requirements.

TSX OR FSX? THE ADVANTAGES FOR YOUR PROJECT WILL IMPRESS EITHER WAY

Flexible and cost-effective for all space requirements machine platform

ProMoCell® adapts flexibly to all project requirements. Based on cost-effective standard components, it grows along with your tasks. And if there is not enough space, the next module can simply be attached.

Easy to relocate at and between your

locations

The modules are easy to transport, including installations, cables and control cabinets. Thanks to their standard dimensions, ProMoCell® modules also fit into any common transport container.

Intelligent software for optimum handling and safe processes

The clever modular concept with its tested modules and feedback function offers maximum efficiency and process reliability. The uniform look and feel of the basic software and drag & drop programming offers exemplary usability with a short training period. Extensive diagnostic functions for hardware and software minimize system downtime. The database connection makes all data available for subsequent processes.

Easy to service, easily accessible and transparent

With its easily accessible maintenance interfaces, well thought-out installation routes and a harmonious lighting and grounding concept, the ProMoCell® simplifies all maintenance and repair work.

Highly effective in occupational and ESD-safety

By limiting production to small and confined working areas, the risks of contamination and system conflictsare minimized. ESD capability ideally protects electronic components.

Safety first!

The sophisticated safety concept enables safe set-up when the safety door is open. The continuous use of safety controllers and extended safety functions on all electrical axes also maximize operator safety.