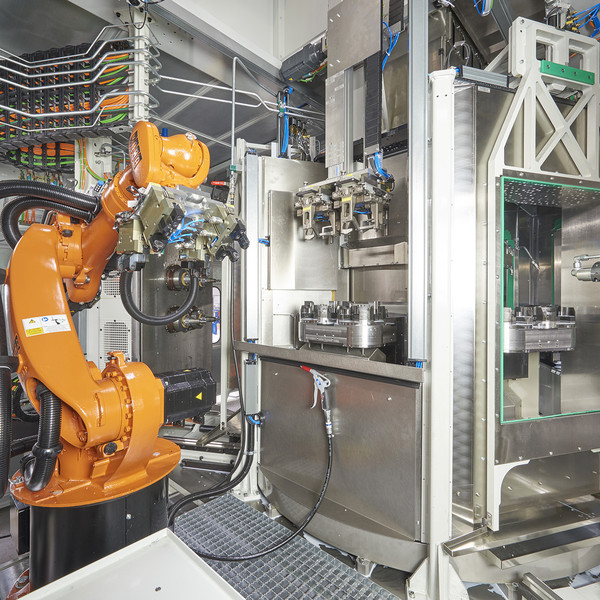

Machining centers for door hinges

Highlights

- Fully automatic rotary table machine

- Every machining station on a 3-axis unit with single- or multi-spindle machining

- 6-sided machining possible

- Highly dynamic rotary table with maximum precision and rigidity

- Fully automatic parts loading and unloading with or without robot

- Complete and multi-sided machining of the workpieces in one set-up

- Wide variety of types by changeable clamping units with zero point clamping system

- Active rotating of the clamping fixture

- Tool monitoring for breakage and wear detection