MACHINING CENTERS - MOST RELIABLE TECHNOLOGY IN TAILORED SOLUTIONS FOR OUR CUSTOMERS

Our machining centers provide a complete machining and are used, for example, in large-scale production of door hinges or engine camshafts for the automotive industry. Quality and precision need to be combined with efficiency and longevity. We rely on proven, continuously developed basic components which are specifically adapted by us for the respective task. With our machining centers there are no limits for your product and variant diversity.

Machining centers based on the ProMoCut® rotary table machines

Our rotary table processing machines offer the possibility of highly productive and precise machining of components.

Our product portfolio also offers high-performance solutions for complex cutting tasks. They are used, for example, in the automotive industry for large-scale production of door hinges or engine camshafts. Our ProMoCut® machining centers (Productive Modular Cutting Technology) provide the possibility for highly productive and precise cutting of the components on a rotary table machine. The standardized modular machine construction system allows machine designs of 2, 4, 6, 8 and 10 stations which are configurable both with one or more spindles.

Cycle times of approx. two up to eight seconds are achieved, depending on the customer product and the required cutting degree. The possibility of performing a 6-sided complete machining while the workpiece remains in one position offers enormous advantages and is the basis for a high quality and process reliability. The existing modular machine construction system is with individual developments optimally adaptable to specific customer needs.

Machining centers

In our machining centers we combine quality and precision with efficiency and longevity.

With our machining centers there are no limits for your product and variant diversity.

Passenger vehicle cam

This highly productive and flexible machine has a very high output of cams produced per year. In the machining centers the cams for passenger vehicles are 2-fold bored and 4-fold broached. The cam machining centers include an integrated cleaning and demagnetizing. Our machines are installed worldwide. To date, our cam machining centers are found at eight locations in six countries on four continents.

Truck cam

Our machining centers for truck cams are built on the basis of the Strama-MPS standard 8-station rotary table machine. This highly productive and flexible machine can align the cams in most different ways and has a high time/chipping volume. In these machining centers the truck cams are cleaned and demagnetized at the same time.

Door hinge

Our machining centers for door hinges on the basis of the Strama-MPS standard rotary table machine allow a 6-sided machining of most different shapes of workpieces.

The number of stations is adapted to the machining tasks and cycle time requirements. Additionally, our highly productive and flexible machines provide loading and unloading either via handling or via robot.

Spider

There are many different variants of spiders available for cardan drives in motor vehicles. As flexible as possible and short-cycle production systems are needed to meet the customer requirements.

Machining centers for cutting and chamfering of the spiders are based on highly productive 4-station rotary table machines providing multi-spindle machining with fully automated loading and unloading.

Tripod joint

We have developed a machining system for tripods to recess slots and to drill centerings. The multi-spindle machining und the fully automatic loading and unloading makes it a highly productive and flexible machine.

Wheel hub

Our machining centers for wheel hubs are built on the basis of the Strama-MPS standard 4-station rotary table machine.

These enable a multi-spindle machining of the wheel hubs and a fully automatic loading and unloading. Complete machining in one set-up.

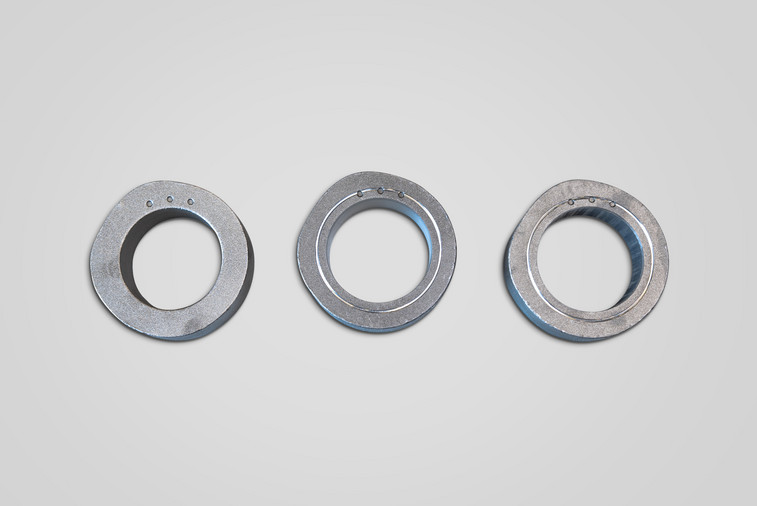

Detent cam

Our machining centers for detent cams are based on the Strama-MPS standard 4-station rotary table machine.

Hard machining as well as fully automatic loading and unloading are integral parts of the machine.

Camshaft tube

The end facing and chamfering machines for camshaft tubes are manufactured according to the Strama-MPS standard 2-station rotary table machine.

Fully automated loading and unloading occurs via robot.

Camshaft

The automatic systems allow the forming of beads, 2-flat, 4-flat and hexagon on the camshaft tubes.

The machining centers are fully automatically loaded and unloaded by a robot.

Hydraulic line

We build automated bending machines for hydraulic injection lines.

The extremely compact and flexible machine is equipped with a fully automatic chaining via robot for forming and inspection tasks.

Needle for injection nozzle

Our special-purpose machines for the grinding of injection nozzles provide an automatic feeding from the magazines and an automatic unloading into the magazines. The grinding wheel with contour-controlled dressing has an automatic balancing system. The grinding process is, of course, monitored. For safety purposes the machine has a CO2 extinguishing system.

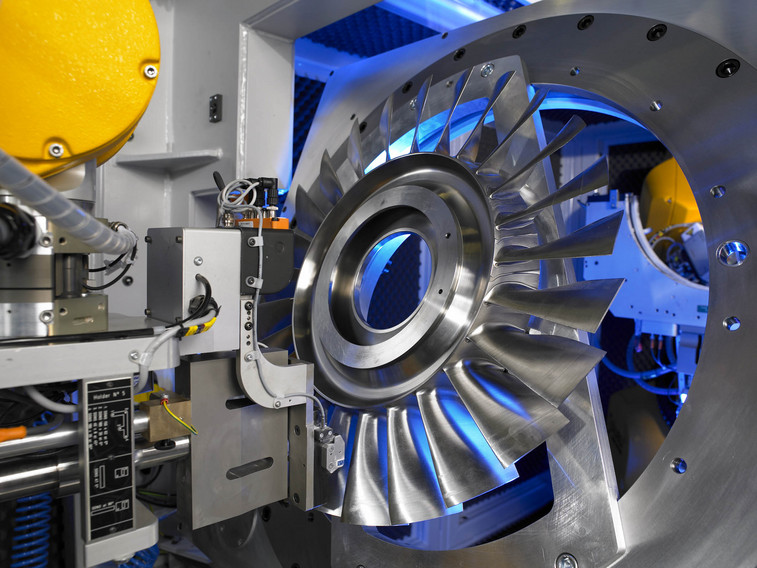

Turbine blade

We build special-purpose machines for the surface treatment of turbine blades.

The workpieces are rotatable and swiveling while clamped and the robot carries special tools for repetitive positioning accuracy.

Further products for machining centers

- Magnesium Retaining Bracket

- Converter Cap

- Oil Pan Carrier

- ABS-Housing

- Chuck Jaw

- Cylinder Head Cover

- Crankshaft

Integrable processes

Cutting Processes: Milling • Drilling • Turning • Boring • Reaming • Countersinking • Thread Cutting • Thread Milling • Broaching • Profile Broaching • Grinding • Brushing • Deburring • Sawing • Hard Machining

Non-Cutting Processes: Rolling (Smooting, Compacting) • Thread Forming • Crimping • Pressing • Bending • Blasting • Marking • Cleaning • Drying • Demagnetizing • Embossing • Deep Drawing • Punching

Integrated solutions

Assembly • cleaning • workpiece measurement • wear compensation • temperature compensation • tool monitoring • chaining of systems • robot integration • MDA/PDA-connection • grinding wheel balancing • fire protection device • force-displacement monitoring • leakage test

Retrofit/Service

Retrofitting • modernization • overhauling • expansion • retooling • repair

Built-to-Print

Fixtures • units • complete systems